Thoughts on Modifications, Partscasters and Kit Building, and DIY Guitar Making in general

This article was inspired by a number of things really, but most recently triggered by a few YouTube videos - by Louis The Tone King and Darrell Braun. I’ve been an avid follower of Louis, Darrell and one Ben Crowe over at Crimson Guitars for a few years now. I have watched all of Ben’s crazy guitar builds and have for a long time been tempted to go on one of the Crimson Guitar Building Courses and make my own axe as it were.

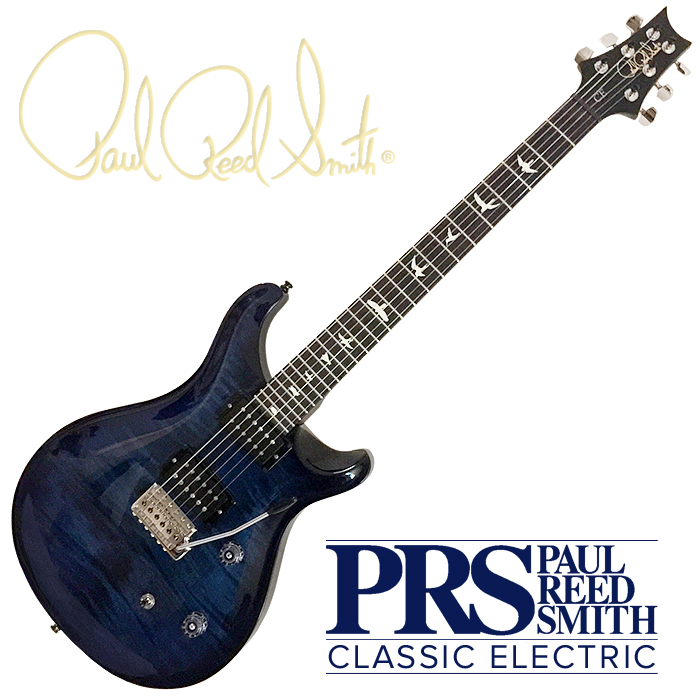

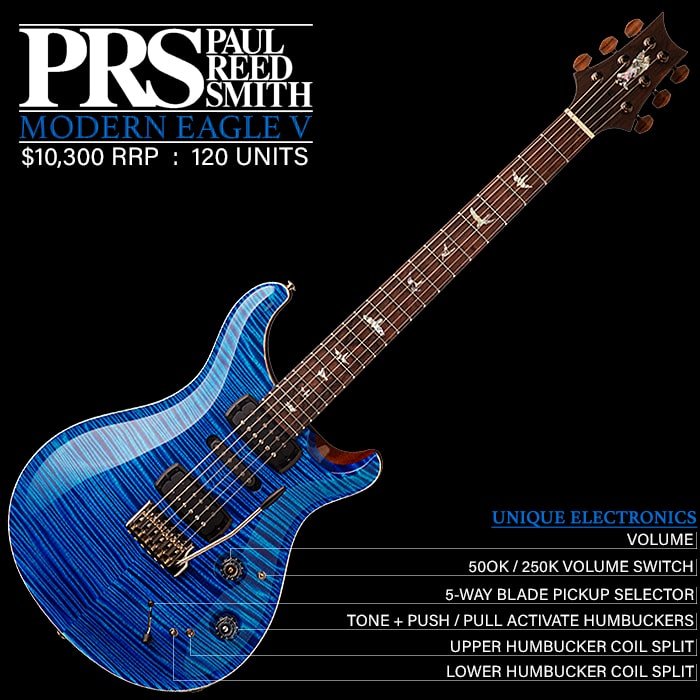

In my recent feature about Guitar Tuning Fidelity, headstock designs etc. I once again reiterated my admiration in particular for guitar makers Paul Reed Smith and Ernie Ball MusicMan. In my opinion those are currently the best-made guitars you can get nowadays. I’m not in the slightest bit a traditionalist, and I’m much more concerned with overall design, attention-to-detail and final quality of instrument. It’s no surprise that much of the production at those two companies is fully computer-processed and automated. Including things like the shaping of the necks, fret slotting and several stages of sanding and polishing. Of course you cannot get away from manual processes, but it’s vital that the various carves and component placements occur with the highest degree of accuracy. Also that you have experienced personnel at each process station with years of knowledge and who know exactly what to look out for.

Whenever I think I should be going to Crimson Guitars and building my own guitar, I cast my mind back to woodworking class in my early school years and recall exactly how many fishing boats, violin-shaped corner shelves and bird houses were actually made pristine. In fact most had myriad small mistakes in measurements and cuts - which were sort of covered up by artful sanding, glueing, lacquer and paint. The trickiest and most vital part of the guitar is the ’Neck’ which takes Master Luthiers years to perfect the technique, so results may vary as to what you can achieve in 6 days or 3 months of your own graft.

So beyond just buying your ideal guitar from a manufacturer - either custom-commissioned or off-the-shelf, you sort of have three choices on how else you might acquire your perfect instrument:

- Upgrades and Modifications - Buy the nearest match model over all - depending on budget and other key factors, and swap out low or average quality parts for premium replacements

- Custom Parts / Partscasters and DIY Kits - go to Warmoth.com or similar and select the parts with which you can assemble your perfect guitar

- Go on a Guitar-Making Course and Build your own - i.e. head off to deepest Dorset to Crimson Guitars for weeks or months in the company of Master Luthier Christopher Owen

All of the above have various pros and cons, and where I am right now, I have an obvious preference in how I would proceed - as well shall see...

Upgrades and Modifications

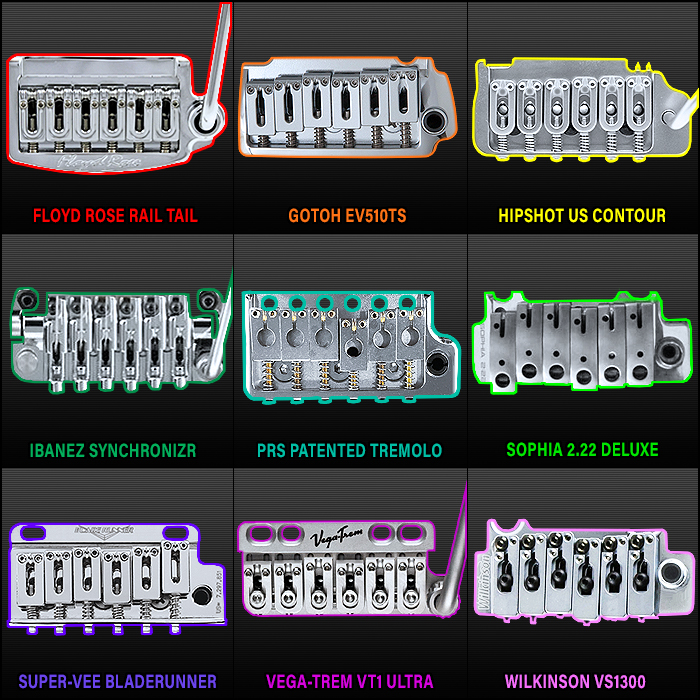

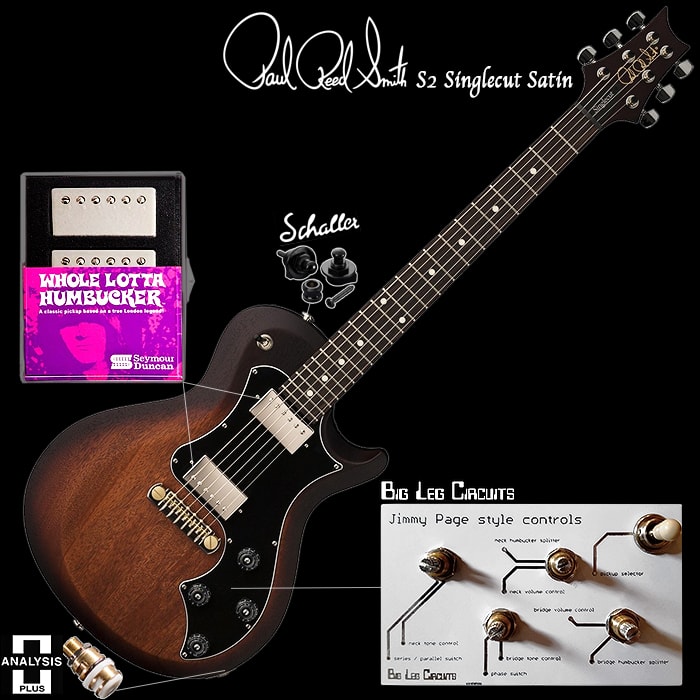

Credit where Credit's due - and this bit is wholly inspired by Louis The Tone King. Last year I was in fact considering acquiring a PRS S2 Satin Singlecut (just stock) - at that time in black (see Singlecut / LP-style article), but now I think I prefer the McCarthy Burst version - where you can see more of the Mahogany wood grain. I have a thing about disliking gloss necks - which most PRS guitars still have - so I stick with the somewhat fewer satin neck models. In any case the PRS S2 range is entirely manufactured and assembled at the core Maryland USA plant, while most of the hardware and electronics are cheaper and lower / average quality Asian import equivalents - that is to say the bridge, tuners, pickups and electronics - where you can see significant improvements from upgrades.

As stated previously - the key factor about a guitar is how well it is built - its final fit-and-finish / tolerances - in particular the various bits of woodwork, and the neck most importantly of all. These are all Core USA made and of the highest quality - although some of the carves have been simplified for cost-savings. So the basic guitar you get new for £999 is a USA-made model with some compromises for cost-savings - to be able to come in at that lower price point.

The guitar in question is also of the scratch-plate type - where the pickups and electronics are mounted directly to the scratch-plate - which makes customisations and upgrades so much more straight-forward. So Louis picked up a really good value second-hand white one of these I think it was and then added all the parts I would have chosen myself - with the exception of not including the Schaller Strap-Locks which are a must for me.

The component count and cost is as follows:

- New PRS S2 Satin Singlecut in McCarthy Burst - £999 (make sure you get newer version with adjustable saddles)

- Seymour Duncan Covered Whole Lotta Humbucker Pickups - £234

- Big Leg Circuits Jimmy Page style Wiring Harness - Pots and Switches - $115 (c£90)

- Analysis Plus Qi Input Jack Socket - $39 (c£30)

- Schaller Black Chrome Strap Locks - £16

Total component cost = £1,369

Plus circa 3 hours of labour.

Louis The Tone King's 3+ Hours Live Upgrade Session

Note that it is Louis's style to regularly disappear from view to fetch a beverage, tool or device or even conduct random tasks - so be ready to forward-wind liberally!

Where I am right now I don't have any soldering skills let alone aptitude for proper luthiery, and would find a local guitar tech to do the work - likely Kevin Bourque of Denmark Street's 'Stairway to Kevin' fame. I estimate a the upgrade and setup would take under 3 hours for a professional. Louis took a while longer, but then he does leave the room on several occasions and takes some time to consult various references.

For me to ensure that the guitar meets the highest specifications - I would most certainly rely on a professional here, but those used to this kind of thing can do it all themselves and save on that cost.

Custom Parts / Kits and Partscasters

I've been enjoying a number of videos from Canadian guitar guru Darrell Braun - who's skill in picking out the best components and artfully assembling them together never fails to impress me. The build of his that struck a chord with me in particular was the black figured maple SuperStrat - where he found online an amazing Warmoth Strat body and superb original Fender Deluxe neck - which is a real rarity. For reasons of ergonomics and efficiency I don't particularly like Fender headstocks - and would rather want to be able to source something like a PRS or MusicMan headstock / neck - or the Warmoth Modern 3+3 even as pictured above.

In any case - Darrell's parts selection here is incredible, and the way they come together over these three videos is really impressive!

Darrell Braun's SuperStrat Project - The Build

Darrel is a dab hand at guitar assembly - it is quite evident that he has quite the aptitude for this type of luthiery. A relatively short build highlights video.

Darrell Braun's SuperStrat Project - The Tones

Of course aesthetics play a key role in instrument preferences - but all is moot if the final product does not sound as good as it looks. All of Darrell's choices are resoundingly validated by a truly great sounding and effortlessly playable Strat - this is a magnificent build project really brilliantly executed!

The Wonder of Warmoth Custom Guitar Parts

Even though I had seen mention of Warmoth before - it was Darrell Braun's videos that really introduced me properly to the possibilities of these types of near-finished guitar kit builds. I had seen lots of kits before which were much rawer and of a much lower quality. Seeing what Warmoth can provide you with is a real revelation - do note though that things can soon get pretty expensive.

To keep to a unified theme for this whole article I might have chosen a classic singlecut body, but I could not find one I really loved on Warmoth, so I selected a beautiful exotic wood 'VIP' style body (Zebrawood on Swamp Ash) which is at $525, and I then specified a Dark Rosewood + Dark Rosewood Neck / Fingerboard with binding - which came to around $500.

The tricky thing about picking out and specifying parts is that you really need to know your stuff here - as you get questioned on all kinds of things like neck profile and radius and nut width. For the uninitiated this can be something of a quagmire - and yes you can make mistakes and find out that you've acquired parts that aren't compatible and don't fit properly together. Even when they do - there will usually be some amount of fine-sanding required.

You can of course buy much rawer kits as mentioned - where much of the woodwork is unfinished - and you need to apply the final finish and refine somewhat the parts you have acquired. It's also far more difficult to achieve a quality finish with a through- or set-neck design compared to a bolt-on - so I would probably limit Partscasting to bolt-on-neck-style models.

In my example just the neck and body together come to a sort of equivalent price to the entire PRS S2 Guitar - meaning that not only do you have to provide pickups, electronics, jack etc. - but nut, machine heads and various fixtures and fittings - assembling a kit guitar is a whole load more work than 'Modding' an existing guitar - and usually is a much pricier route if you want something of comparable quality.

Note also that with Darrell's Partscaster he was dealing with a sratch-plate-type guitar which more naturally lends itself to DIY builds and modding in general. The Warmoth example might require a degree of additional routing and trimming - depending on the electronics and pickups you select - while these things are easier to sort when most of those are attached direct to the scratch-plate.

I am still much encouraged by Darrell's build - but doubt I have the requisite skills to do the process as much justice as Darrell obviously can - probably something for later years!

Guitar Building Courses

So this is the Full Monty exercise here really - building the whole guitar from scratch - and having to make all kinds of off-the cuff decisions as you try to perfect your own instrument. Remembering that the most trickiest part here is the Neck Carve, and Fretboard fretting and inlays. At Crimson - a lot of this is still largely finished by hand - which difficulty is more acute if you navigate outside of Crimson's core template library like many of the students do.

I think specifying and building your own guitar is a major goal for lots of guitarists, but there are so many caveats to be aware of. I always say you are best served by not just knowing what you're good at, but knowing also what your limitations are - and that the chance of you achieving PRS or MusicMan - levels of quality with your first, second or third personally hand-made guitar are slim to none.

I always cast my mind back to woodworking class and remind myself how disappointed I was with certain aspects of the finished articles. Sometimes I was really rather proud of the quality I achieved, but often I was sort of annoyed at the flaws that I knew were in the final build. With Guitar Luthiery - it can be a very fluid process, and a great deal of it is about overcoming mistakes and 'rescuing' or resolving a build in progress. And hand-making guitars from scratch is both a laborious and time-consuming task - which would likely leave my palms raw. Yet I still harbour aspirations that one day I might be good enough to build by own idealised guitar - a sort of PRS 513 with improved switching, hardware and ergonomics - but then the cost of achieving that may be as prohibitive as a custom-shop / Private Stock commission through official channels.

I watched Adrian Thorpy of ThorpyFX create a very specific guitar for himself (video below) - which was not readily available elsewhere. Of course he could have commissioned one from any number of Master Luthiers - but he is himself a skilled craftsman, well used to spending hours at a workbench. He went into the process fully knowing what he wanted and with everything finely planned and set out. In going through such a process there are all manner of lottery style choices - even at the most basic level - finding the right woods for your build. And most builds end up as a series of compromises - however minor. You usually go into a build with lofty ideals, but then find that the practicalities are somewhat more tricky than the plan indicated that they would be. These can be tiny differences in measurements or the tiniest degrees of inconsistency in stain or glue application or being slightly heavy on the chisel or orbital sander - the pitfalls you will face are myriad.

So ideally you need to go into the process with everything fully planned out in advance, but be prepared to make all manner of off-the-cuff decisions while in the process. For a perfectionist like myself I feel I would be too overtly critical of any tiny flaws made, and they would weigh heavily on my conscience ever after.

The two practical extremes of pricing are £995 for a 6 day course, and £4,195 for a 3 month course. For my own needs I would probably need something in the middle to get a decent result - and then I would need to factor in the various material and component costs on top of that - knowing that there are certain types of finish and details that the Crimson facility might not be able to accommodate.

I think if you really know what you want, and are reasonably and pragmatically minded, then this could well be something for you. If you are an OCD Perfectionist - this though could be the stuff of nightmares for many years to come. I kind of swing from really wanting to try this out to thinking that there are other people far more adept at doing this sort of thing than I, and that I could probably achieve better results by other means.

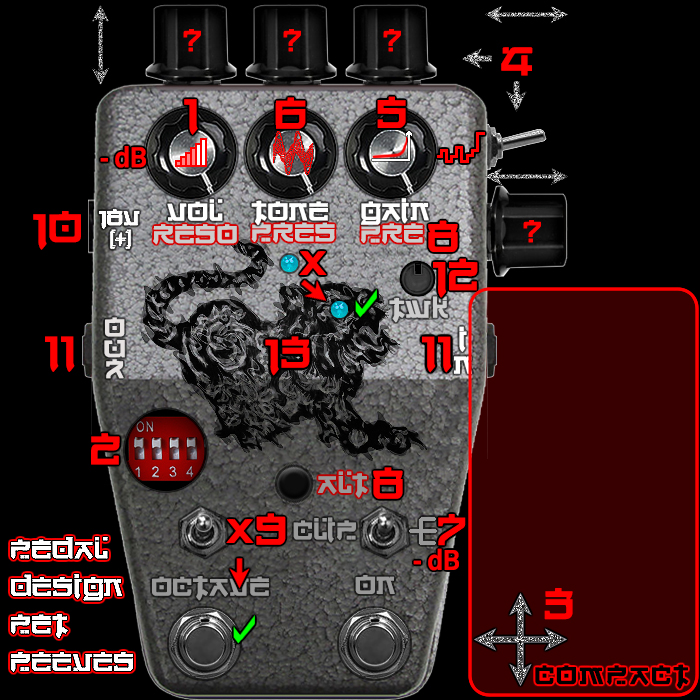

I think I might also be better served using the Crimson course as a sorted 'assisted build' in doing a Tone King or Darrell Braun style guitar project - using pretty highly finished parts and just needing to assemble them really - with bits of fine sanding, soldering and fine-tuning. I think this would probably be a good starting point for most budding guitar builders - just like most pedal builders start off by making relatively slight modifications to already existing and already pretty great pedals!

Crimson Guitars What's On The Bench Episode 110 - including a brief catch-up with Adrian Thorpe of the already legendary ThorpyFX

Thorpy is one of the pedal builders I really admire - and it's interesting to see what guitar he has decided to use the Crimson process for. I have to say that I don't like a lot of the Crimson default templates - the Descendant models and headstock shapes for instance - while I am a fan of many of the Custom Projects and Master-Built guitars in particular.

It's interesting to see that Thorpy takes himself outside the more typical Crimson templates. I admire much of what Ben Crowe and crew do - and in particular have a lot of respect for him and Christopher Owen in particular - I just wish they would improve the symmetry of their standard / default models. I also wonder about longer-term ownership and maintenance of some of the rawer guitars they build - which can have quite a lot of 'exposed' wood as it were.

They're definitely one of the companies that popularised the trend for more interesting wood use - where lots of those pieces may have been classified as off-cuts and waste previously. I do feel though that Crimson Guitars are generally quite expensive relative to their overall quality - and that I can get better made guitars for a better price elsewhere. All food for thought in any case - even though overall I really admire the operation.

Final Thoughts

Where you are on a daily basis can vary hugely, and sometimes you are more predisposed to one thing over another or one way over another - depending on how you are feeling exactly then. Of the three scenarios above I can see myself quite easily indulging in the first two, with the PRS S2 Upgrade a total shoe-in.

Right now I'm really not convinced as to the merits of making my own guitar from scratch - I don't really need the accolades or self-satisfaction or admiration even - I am just interested really in being able to acquire the best and most efficient and playable instrument for my own needs - in the highest quality and most efficient manner possible and within acceptable limits of cost etc.

So it obviously helps having a head start on the process - by for instance working with the best available materials from the start - rather than having to build every part within your own personal / technical limitations.

As with anything in life I think I would need to work my way up the scale - as I have in fact not done anything of a woodworking nature for many decades now. I reckon the Parts Upgrade Path is doable for most - albeit I will even farm out the heavy lifting part of that. Possibly I could go on some courses on basic assembly and full guitar setup procedures and then calibrate my skillset to the relevant category. I'm still not sure I would want to spend several days worth sanding wood though? Remember that whichever route you take - results and costs can vary immensely!