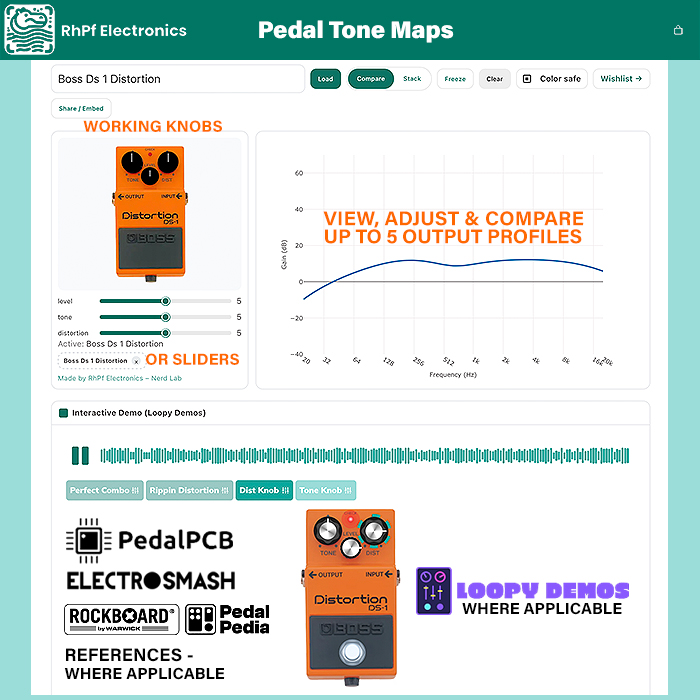

An Extended Primer on most everything to do with Effects Pedal Capacitors - in collaboration with Joe Halliday of Hello Sailor Effects

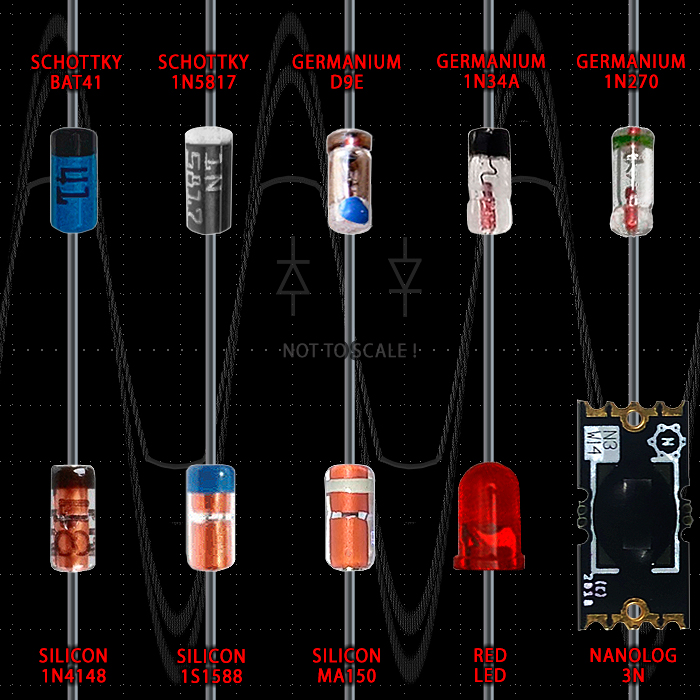

The most popular post on this blog to date is ’A Brief Hobbyist Primer on Clipping Diodes’ which has to date been read 117,610 times! It was always on the cards to follow up that article with deep-dives into Capacitors and Resistors too. I wanted to be even more encompassing than before - and go into more detail - and it was a matter of finding the best possible partner and collaborator for that task.

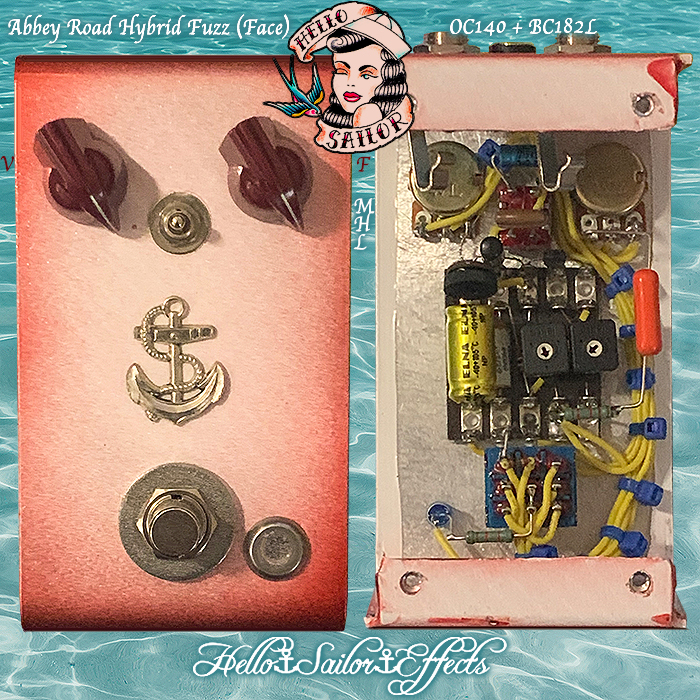

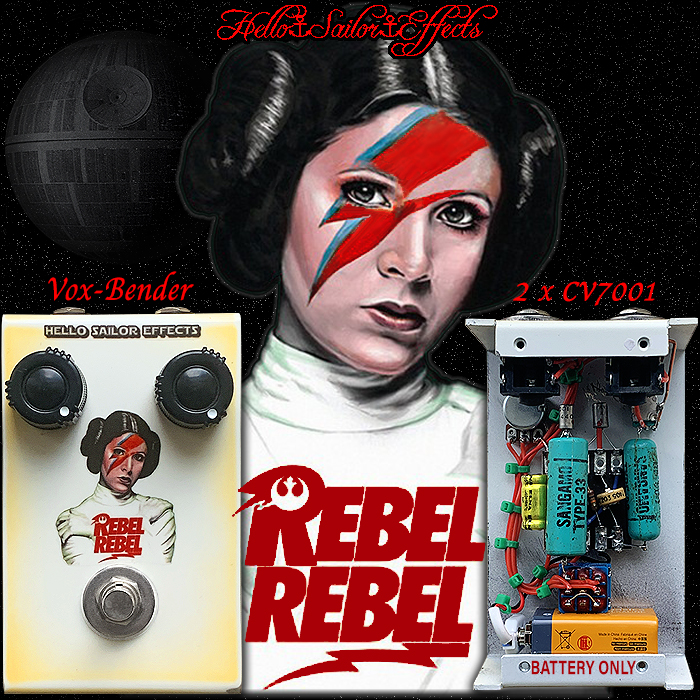

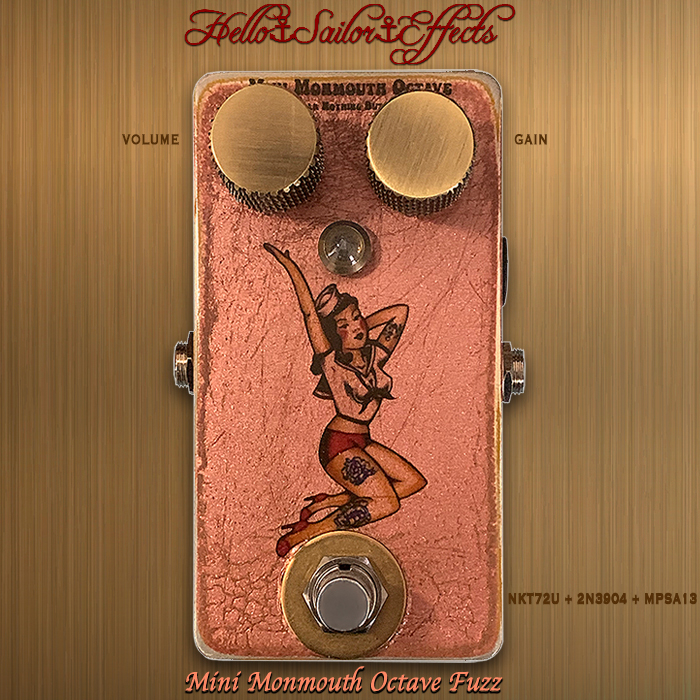

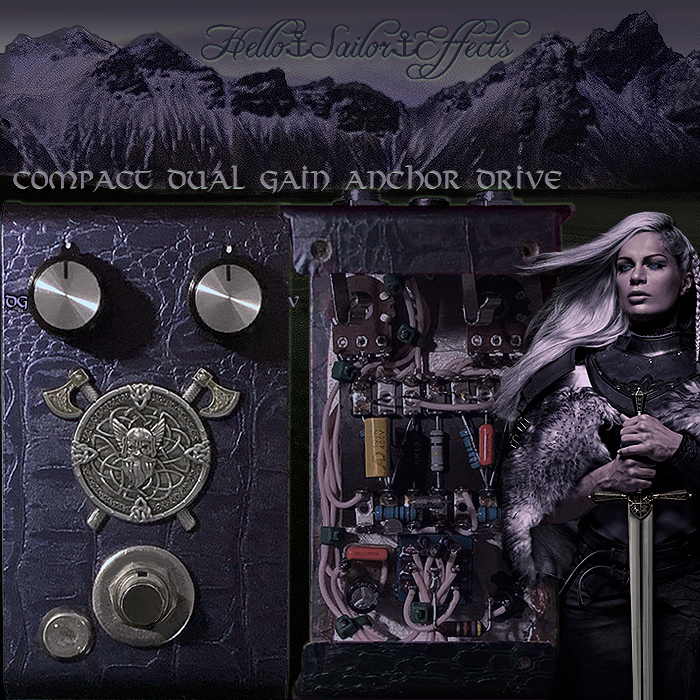

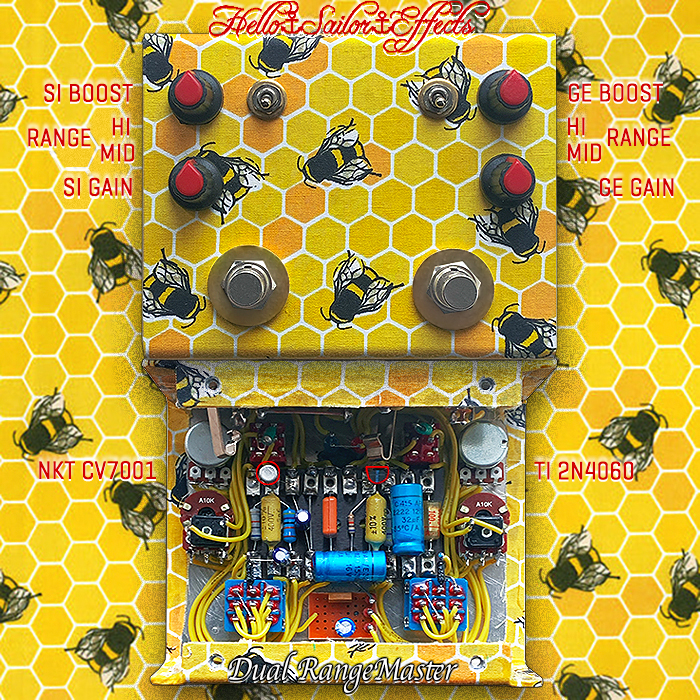

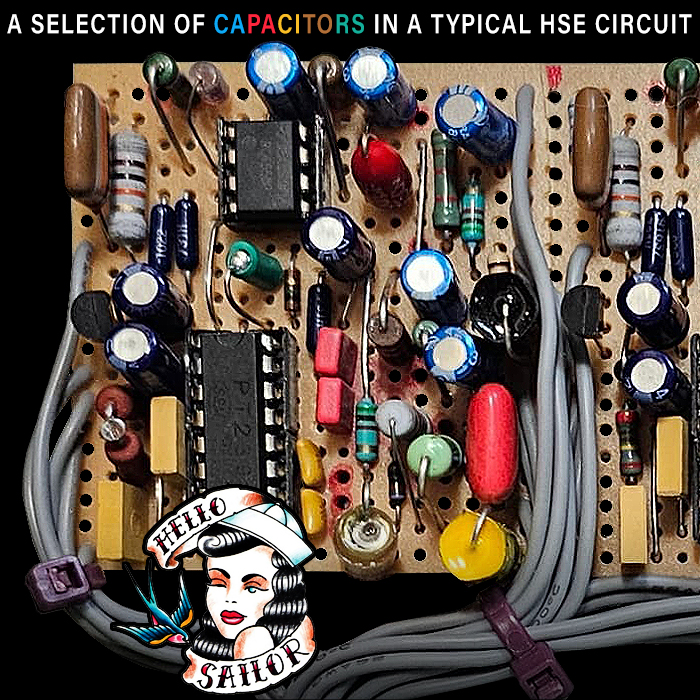

And no one has a deeper exotic-filled parts bucket than my good friend Joe Halliday at Hello Sailor Effects. He was an equal partner in this enterprise - and I could not have done this without him! Hopefully we will be doing the same exercise on Resistors in a month or few!

Of course there are other articles on Capacitors out there - but nothing I’ve seen close to this magnitude - I’ve scoured 100’s of resources to aggregate the most pertinent and detailed insights into capacitors to date - where I tackle various Capacitors (mainly those used in audio circuits) - in every practical way possible!

This feature presentation has 9 sub-chapter headings :

- Capactitor Inventions and Innovations Timeline : 1745 to Present

- What is a Capacitor and How does it work?

- Measuring Capacitance

- Capacitor Lifespans [NEW]

- 6 Key Audio Circuit Capacitor Material Types

- The 4 Key Uses of Capacitors in Audio Circuits

- Insights into specific Capacitor Values

- 14 Key Iconic and Historic Audiophile Capacitors

- The Myriad Capacitor Electrical Circuit Symbols and their meanings

Joe and I do hope you enjoy this journey into the technology of sound!

Capacitor Inventions and Innovations Timeline : 1745 to the Present

I will start here by saying that this Timeline exercise was a lot more complex than indicated on the surface - and that it had several iterations along the way.

As with most history - the core facts aren't necessarily in dispute - while many of the details are. That's why the Leyden Jar is 1745/6 as some say 1745, and others say 1746. In general there is a complexity here as inventions and prototypes happened way before patent registration - and those devices actually getting into general circulation - so the dates can vary. Also there is disagreement as to the definition of different types - and depending on various interpretations - you get a different data set each time. I've aggregated a number of of sources here - and tried to fully rationalise the timeline - but some elements are sill under dispute.

Moreover there is very little solid / pictorial evidence of those early devices. Few were preserved - as those containers were subsequently used in other different experiments - Labs have limited real-estate - and elements get re-used and evolved over and over again. So we basically have some scratchy illustrations for some of those earlier devices. And for instance the Variable Capacitor it not the first original one, but something similar that evolved a little later - and for which there is a solid reference. I've tried to find the best pictures to illustrate the key timeline entries - but some of those are slightly 'fudged' on occasion. It still makes for a highly intriguing collection of artefacts!

1745 / 6

- Invention of the first capacitor device - the 'Leyden Jar' by Ewald Georg von Kleist - the Dean of Cammin in Pomerania. Ewal discovered that a large glass water bottle lined inside and out with some metal foil, and with a an exotic sort of metal anode stopper - he was able to capture significant amounts of electrical charge. The very original glass jar looked more like an exotic milk bottle with extravagant stopper - while subsequent models looked more like those barbershop glass jars that are used to sterilise barber shop equipment. Most of the earliest capacitors were glass vessels. While early on these were known as 'Condensers' - including Tesla's patent for a Vacuum Condenser. It was only later that the word 'Capacitor' became the defacto label for these devices - while for a period they were variously called Condensers and / or Capacitors!

1782

- Alessandro Volta was the first to name these devices as 'Condensers' as of 1782. It was actually only really in the early 1900's where Condensers came to be more commonly known as 'Capacitors'.

1830

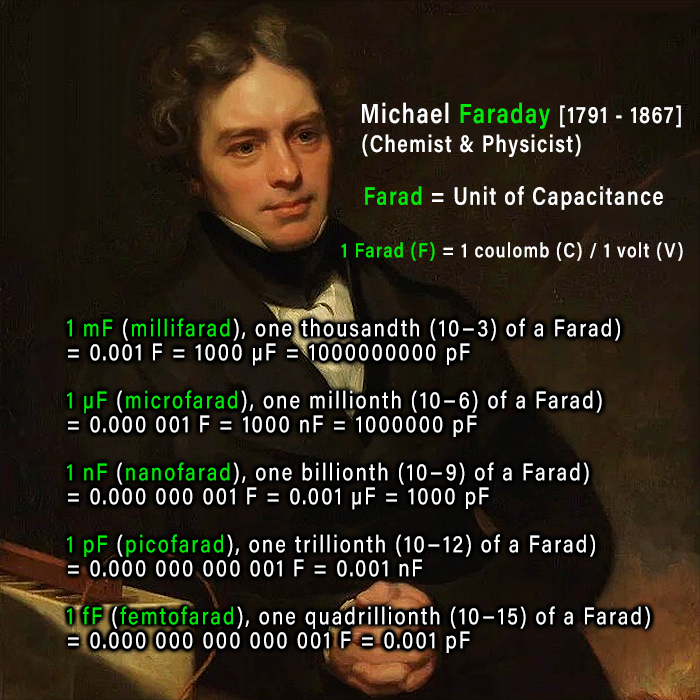

- The origin / naming of the Unit of Capacitance was drawn from notable Scientist / Chemist / Physicist of the time - one Michael Faraday [1791-1867]. 1 Farad is the equivalent to 1 Coulomb (Electrical Charge) per 1 Volt. And where the Coulombs are calculated by multiplying the amperage / milliamps by the seconds of duration.

1876

- The Invention of the first Paper / Molded Paper / Wax Paper capacitor by D.G. Fitzgerald - which took over from those various Leyden style glass jars. There is still some dispute as to the particular nature of this material construction and some conflate it with Paper-in-Oil caps because of the Paraffin Wax used - while for most those two quite different methods of construction! These were also referred to as 'Film Capacitors' while that now indicated a somewhat different construction!

1893

- A Mechanical Variable Capacitor with 'Air Dlelectric' was first invented by Hungarian Engineer Dezső Korda - who received a German Patent for his invention in December of 1893. It would have looked similar - but not identical to the pictured variant - which is a slightly later model. Incredibly steam-punk looking for an electrical device - and kind of a sign of the time - as with all the material enhancements in the different periods of Capacitor manufacture!

1896

- In said year Nikola Tesla was awarded U.S. patent 567,818 - for the first Vacuum Capacitor, or : "Electrical Condenser - 1896 September 15 - Condenser constructed or provided with means for exclusion of air or gas; Armature composed of a conducting liquid; Armatures in two separate bodies of conducting liquid insulated electrically and contained in a receptacle; Insulating liquid seal on the surface of the conductive liquids"

1909

- Wiliam Dubilier developed smaller Mica capacitors used on the receiving site of resonant circuits for wireless hardware, These early Mica capacitors consist of layers of Mica and Copper foiled which were pinned / clamped together - and came to be know as 'Clamped Mica Capacitors'.

1910

- An early variant of 'Plastic' Film Capacitors using Cellulose Acetate were developed.

1920's

- A particularly busy period for Capacitor Innovation - which ushered in :

- Paper in Oil Capacitors

- Wet Electroytic Capacitors

- Early Ceramic Capacitors (including Porcelain!) Mostly tubular metal originally (similar to pictured example) - quite different to the Japanese Disc shapes that evolved later!

- Silvered Mica Format Capacitors

1925

- Witnessed Dry Electrolytic Capacitors becoming the dominant formats

1930

- More robust and reliable Tantalum Electrolytic types started being rolled out - particularly for military applications

1950's / 1952

- Plastic Film PET types started to dominate - Polystyrene, Polyethylene Terephthalate, Cellulose Acetate, Polycarbonate, Polytetrafluoroethylene, Polyparylene, Polypropylene, Polyethylene, and Polyphenylene Sulphide. These also included a variety of product names at the time - like Dupont's 'Mylar' which was simply its formulation of Polyethylene Terephthalate. Obviously 'Plastics' were huge in the 50's - with Bakelite and other similar brands too - and for every era of material manufacture - Capacitor production kind of moved in step with prevailing trends!

1957

- The origin of Dual-Layered Supercapacitors and Ultracapacitors - often in the 'Coin-Cell' disc-shape pictured - where I've selected a somewhat unbranded and anonymous variety of that to represent the genre. I was trying to find an original General Electric one - but as with many of the entries here - there was no trace for that!

1960

- Niobium style Electrolytic Capacitor were developed in part to replace the more scacerly available Tantalum material. For some countries Niobium was more readily at hand - and fulfilled a similar highly robust industrial purpose. Most of the Niobium ones nowadays seem to be flat stacked SMT Capacitor types - like the multiple orange Kyocera styles.

1980's

- We started to see various Surface Mount Technology tinier capacitors - I for long mistook those barrel ones as being small THT designs. Where they're now mostly those round barrel style ones for electrolytic capacitors - alongside those flat orange Niobium ones - also electrolyptic types!

2000's

- Capacitors featuring the new 'Graphene' wonder-material start to appear - those are sort of evolved varieties of the dual-layered Supercapactiors / Ultracapacitors - mostly for industrial and automotive purposes!

What is a Capacitor and How does it work?

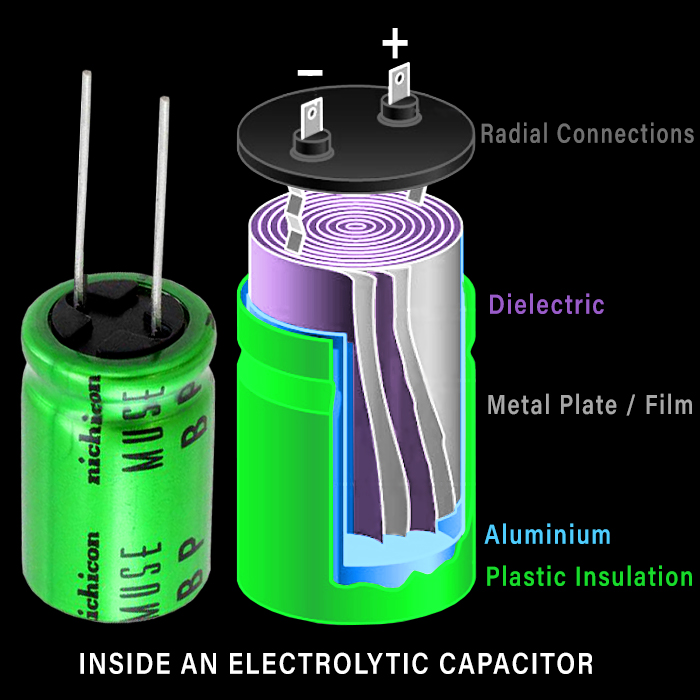

A Capacitor is a device that stores electrical energy by accumulating electrical charges on two conductive plates separated by an insulator (dielectric). When a voltage is applied, electrons flow onto one plate, creating a negative charge, while the other plate simultaneously loses electrons, becoming positively charged. This separation of charge creates an electric field, storing energy within the Capacitor. Capacitors can charge and discharge quickly, making them useful for applications like smoothing out power surges or generally filtering electrical signals.

Over the years we've always had some sort of metal plate / film for a Condenser / Capacitor device - while the Dielectric Insulator and actual nature of containment have evolved with industrial technological advances - and particularly in the area of material science. Where the very original ones were large glass jars, while nowadays we tend to have mostly plastic devices - mostly either Electrolytic - whether Aluminium, Tantalum, or Niobium, or else we have the other popular choice - the PET style Film Capacitors - which are made from several different 'Poly-' plastics - including variants of Polyethylene!

For our typical example of a capacitor we've selected an Electrolytic type as the most common representative (Aluminium) - which I've given the same colours as the Nichicon Green Muse types - just for continuity - where I very early on settled on Green as being the accent colour for his article. You can clearly see the nature of construction here - where this is one of the main formats - or cyclical / circular barrel style - where there are also flatter squarer layered and dual-layered editions - which form the other major variety. Most of the modern applications are either Electrolytic or PET Film - where those intended for industrial use tend to be Tantalum or Niobium constructions versus the more mainstream Aluminium.

Capacitors come in various shapes and sizes where most modern applications tend to be Surface Mount Miniatures - which have significantly smaller profile that the Through-Hole variants. Capacitors also come in Radial or Axial Connection variants - were Radial means that the Positive and Negative terminals are on the same side of the device - or 2-prong, where Axial means that the connecting wire goes hough the capacitor and you have Positive and Negative terminal on the opposite sites of the device. So in our example we see a Radial example - in the main visual most are actually Axial - while the Radials make up a significant portion of the bottom row!

Measuring Capacitance

Capacitance is typically measured using a digital multimeter (DMM) that has a capacitance measurement function. The multimeter charges the capacitor with a known current and then measures the resulting voltage to calculate capacitance in fractions of Farads - which is the unit of measurement for Capacitance - named as a tribute to the great British Chemist and Physicist Michael Faraday - as pictured above. It's crucial to discharge the capacitor before measurement and to select the appropriate capacitance range on the multimeter.

1 Farad = 1 Coulomb / 1 Volt

A coulomb (C) is a unit of electric charge, and one coulomb is equivalent to approximately 6.242 x 10^18 electrons. Essentially, it's a large quantity of electrons, as one electron carries a very small amount of charge.

And where a Coulomb is the value of Amperes x the number of seconds over which the charge occurs.

For audio applications we tend to work in Micro-, Nano-, or Pico-Farad denominations / order of magnitude. Which are tiny fractions of Farads - per the below referenced scale.

Audio Capacitor values typically range from picofarads (pF) to thousands of microfarads (µF), depending on the specific application. Common values for film and C0G/NP0 ceramic capacitors range up to 1µF, while electrolytic capacitors can be found in values up to 10,000µF or even higher.

- 1 mF (millifarad), one thousandth (10−3) of a Farad) = 0.001 F = 1000 μF = 1000000000 pF

- 1 μF (microfarad), one millionth (10−6) of a Farad) = 0.000 001 F = 1000 nF = 1000000 pF

- 1 nF (nanofarad), one billionth (10−9) of a Farad) = 0.000 000 001 F = 0.001 μF = 1000 pF

- 1 pF (picofarad), one trillionth (10−12) of a Farad) = 0.000 000 000 001 F = 0.001 nF

- 1 fF (femtofarad), one quadrillionth (10-15) of a Farad = 0.000 000 000 000 001 F = 0.001 pF

Capacitor Lifespans

Capacitor Lifespan varies enormously by type and method of construction and operating conditions - with film and ceramic capacitors lasting for decades, while electrolytic capacitors have a limited life of several thousand hours (less than 6 months) to a few years, depending on temperature and operational stress. A capacitor's actual lifespan is defined by its operating temperature, voltage, and current, with lower temperatures and reduced stress extending its life. Electrolytic capacitors degrade over time due to electrolyte drying, which causes a loss of capacitance and an increase in ESR (Equivalent / Effective Series Resistance).

Factors that influence lifespan include 1. Operating Temperature, 2. Voltage and Current, 3. Capacitor Type and Construction, 4. Quality of Materials and Manufacture, and 5. Method of Storage

- 1. TEMPERATURE - The most critical factor, especially for electrolytics. According to the Arrhenius equation, lifetime roughly doubles for every 10°C decrease in temperature.

- 2. VOLTAGE and CURRENT - Operating a capacitor above its rated voltage or with significant current flow accelerates its degradation.

- 3. CAPACITOR TYPES and CONSTRUCTION - Different types have inherent differences in their construction and materials, leading to different lifespans.

- 4. QUALITY of MATERIALS and MANUFACTURE - Higher-quality capacitors with better materials generally offer longer and more reliable lifespans.

- 5. METHOD of STORAGE - certain capacitors are more sensitively to humidity and damp and other ambient conditions. Vacuum-sealed, temperature-controlled capacitors in a proper storage facility will significantly outlast capacitors somewhat exposed to the elements.

LIFESPAN by CAPACITOR TYPE

ELECTROLYTIC CAPACITORS (WET) - These have a finite lifespan due to their liquid electrolyte, which can dry out. Their design life is specified at a maximum ambient temperature (often 105°C) and can range from 1,000 hours (1.4 months) to over 10,000 hours (1.14 Years) - of continuous use. In a typical consumer product, they might last 1 to 5 years, though the lifetime is highly dependent on the operating conditions.

FILM CAPACTIORS - Known for their long life, these can last tens of thousands of hours or longer. A 60,000-hour rating (c.7 years) is noted for one type of film capacitors.

CERAMIC CAPACITORS - These are also known for their durability and can last for a very long time - several decades or longer.

SOLID / POLYMER CAPACITORS - Solid polymer and aluminum polymer capacitors offer a significant lifetime advantage over traditional electrolytics, with some rated for over 200,000 hours at 65°C (23 years).

CALCULATING LIFESPAN

Manufacturers provide formulas, often based on the Arrhenius equation, to estimate a capacitor's life under different operating conditions. This involves understanding the relationship between temperature and degradation.

There is suppsedly no single universal 'equation' for calculating capacitor lifespans - it is rather an iterative process using the formula : Calculated Lifespan = Base Lifespan × Temperature Factor × Voltage Factor × Current Factor. The Base Lifespan is provided by the manufacturer under rated conditions, while the factors are calculated based on the actual operating conditions (temperature, voltage, and ripple current) and the fundamental principle that every 10°C decrease in temperature doubles the lifespan of an aluminum electrolytic capacitor, and vice versa.

Further Insights from Joe :

Capacitors actually degrade faster when they sit unused, since the dielectric layer inside them weakens over time without regular voltage applied. If they are left discharged for years and then suddenly hit with full high voltage, they are much more likely to fail. That is why vintage valve amplifier owners often bring old amplifiers back to life slowly with a variac, gradually increasing the voltage so the capacitors have a chance to reform and stabilise instead of breaking down.

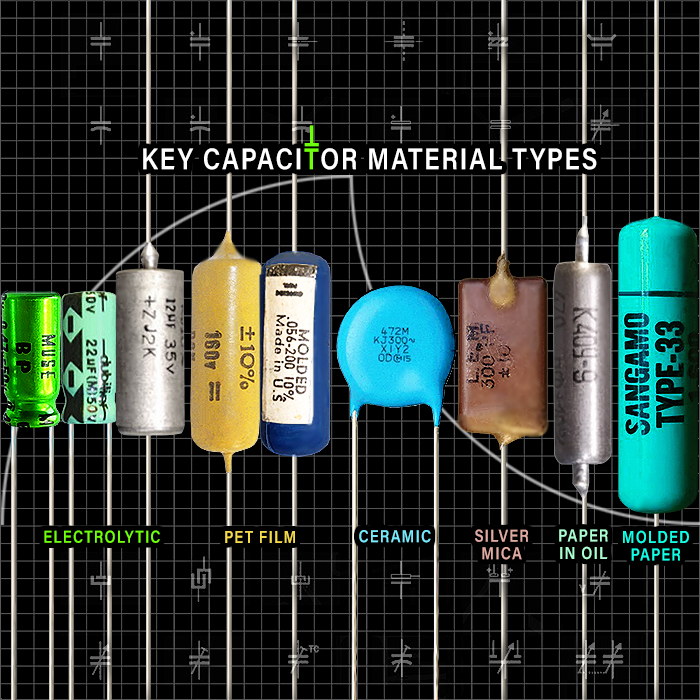

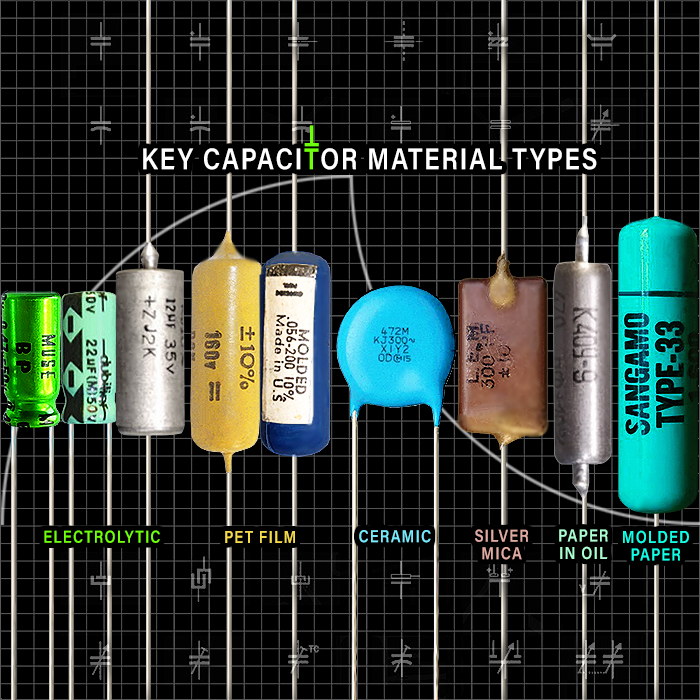

6 Key Audio Circuit Capacitor Material Types

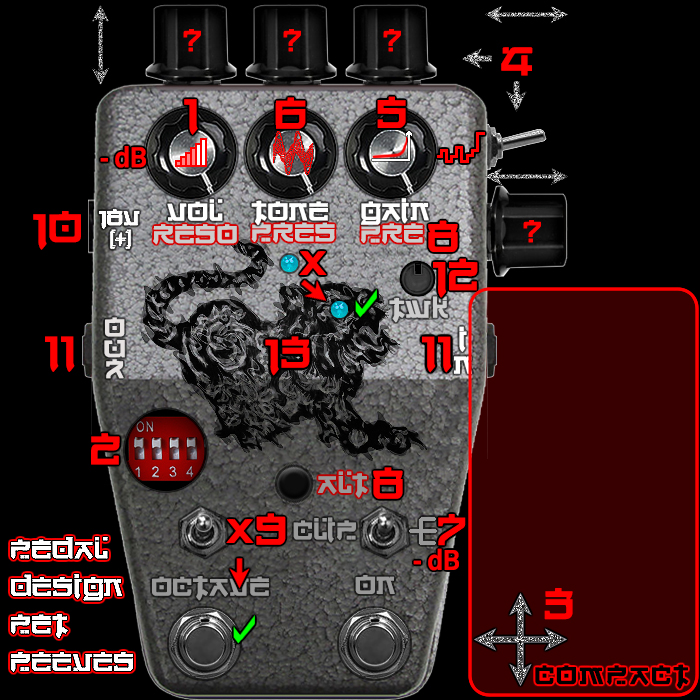

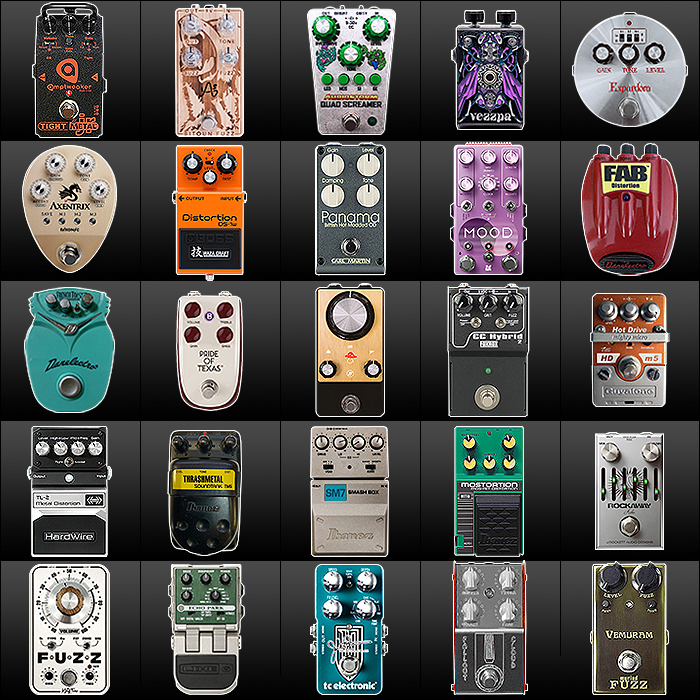

There are of course numerous industrial applications for Capacitors which consist of incredibly large devices with very specialist constructions. For our purposes - we're focusing here solely on the key types used in Audio Circuit Applications - you will find them in a wide variety of electronic applications - including of course in amplifiers and in effects pedal circuits. Nearly every classic effect pedal there has even been consists of Resistors, Capacitors and Tone-generating Tubes / ICC's / OpAmps / Transistors. In that magnitude of number of components - so Resistors typically are the most frequent components - followed by Capacitors.

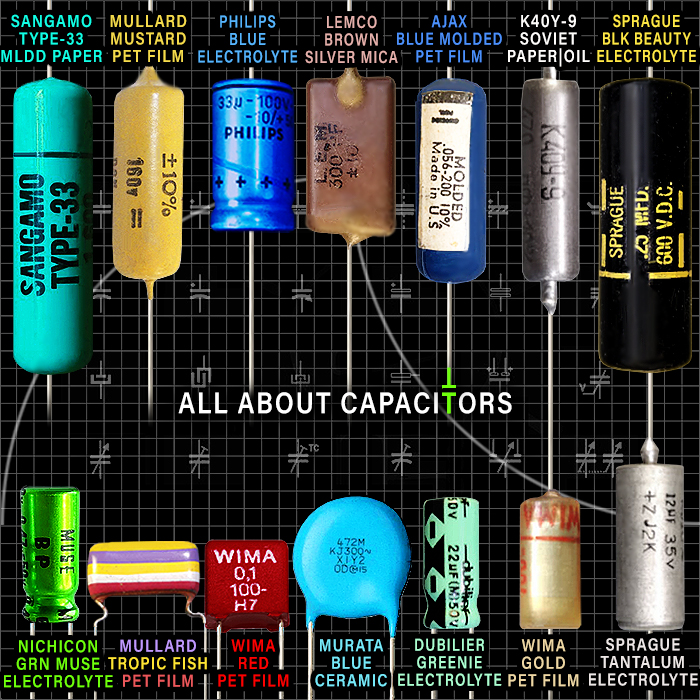

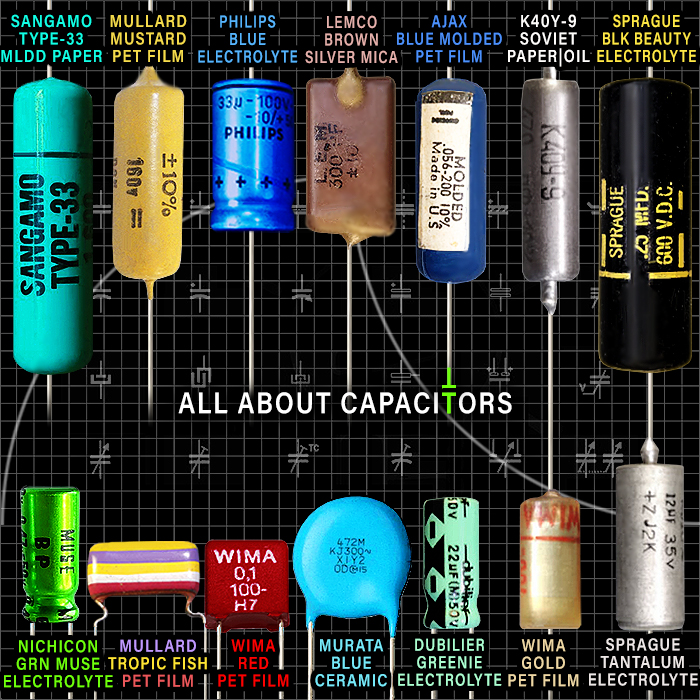

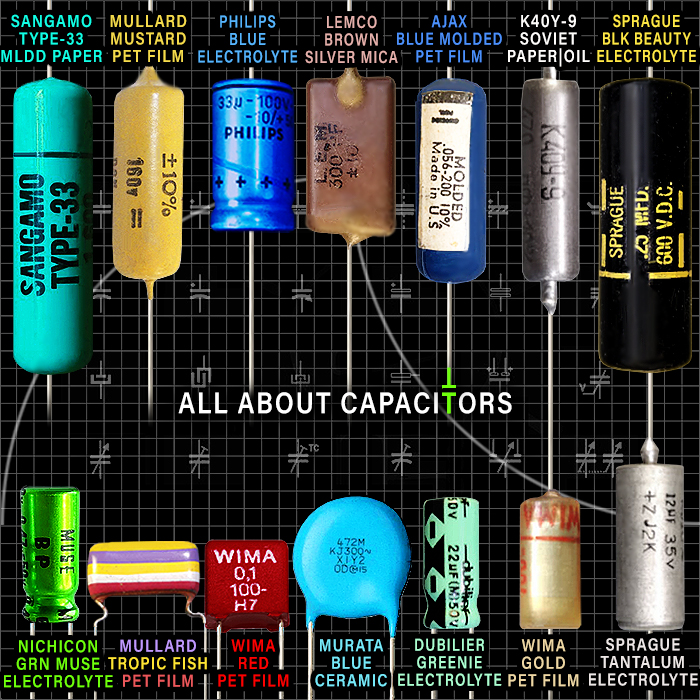

I've already mentioned the dominance of Electrolytic and PET Film Capacitors in contemporary manufacturing - here are the 6 key historic types - as featured in the main visuals!

ELECTROLYTIC CAPACTIORS

Sub-Types - Aluminium, Tantalum, and Niobium.

Examples : Philips Blue, Sprague Black Beauty, Nichicon Green Muse, Dubilier Greenie, Sprague Tantalum.

METALLIZED PET FILM CAPACITORS

Sub-Types - Polyester, Polypropylene, Polystyrene, and Polycarbonate.

Examples : Mullard Mustard, Ajax Blue Molded, Mullard Tropical Fish, WIMA Red, WIMA Gold.

CERAMIC CAPACITORS

Sub-Types - MLCC, C0G, X7R, Y5V, NP0.

Examples : Murata Blue Disc.

SILVERED MICA CAPACITORS

Sub-Types - Clamped Mica, Silvered Mica.

Examples : Lemco Brown.

MOLDED PAPER CAPACITORS

Sub-Types - Wax Paper, Plastic, Epoxy.

Examples : Sangamo Type-33.

PAPER-IN-OIL CAPACITORS

Sub-Types - Various Oil-Impregnated Papers as Dielectric, typically Mineral Oil

Examples : K40Y-9.

JOE's INSIGHTS

There are loads of different capacitor types out there, but when it comes to building pedals, these six material types are the big hitters. First up are electrolytic capacitors, usually made with aluminium, though you’ll also find tantalum or niobium in certain designs. They are polarised, meaning they have a positive and negative leg, and they are typically used for bulk filtering, power supply decoupling, or anywhere you need big values in a small package.

Next are metallised PET film caps, which come in materials like polyester, polypropylene, polystyrene, or polycarbonate. These are non polarised, stable, and great for signal paths and tone shaping.

Then there are ceramic capacitors, which are the tiny round disc shaped ones. They are cheap, common, and useful for decoupling or high frequency work, but not always the most stable for audio tone.

Silvered mica caps are the high precision types often used in treble circuits or old school EQ stacks.

Moulded paper capacitors are less common these days but still turn up in vintage gear and tend to sound warm and slightly lossy.

Finally, paper in oil capacitors are the boutique favourites, known for their smooth, rich tone in guitar amps and high end pedals. Each one has its place depending on the circuit, so it is worth getting a feel for what they do before choosing parts just by value.

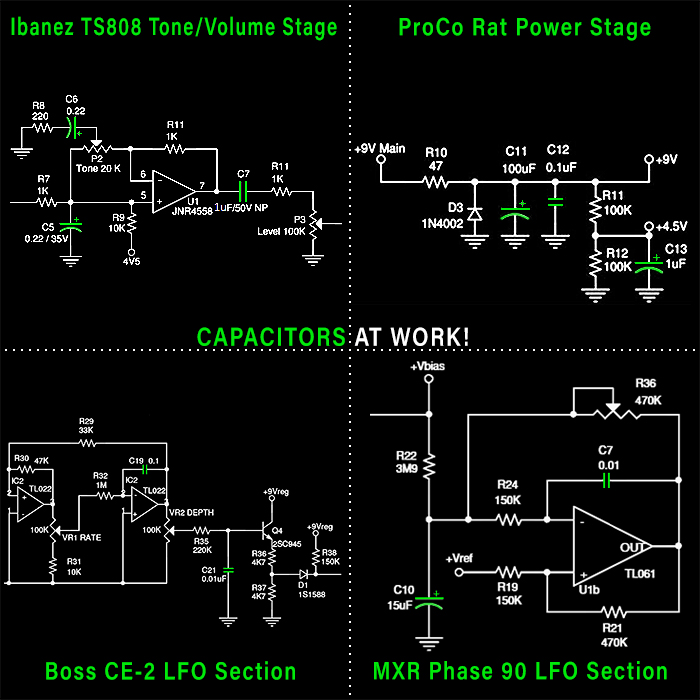

The 4 Key Uses of Capacitors in Audio Circuits

- Tone-Shaping / Filtering - High Pass Filters, Low Pass Filters, Frequency Selection

- Power Coupling - Coupling is Blocking DC current while filtering out AC current

- Power Decoupling - Decoupling is used for Power Filtering and Smoothing, and Noise Floor reduction

- Timing and Modulation Regulation - For Delays, Tremolos and Choruses capacitors help regulate modulation timings

Key Pedal Usage Examples include - Treble Bleeds, Tone Controls, and Power Filtering (reducing noise floor)

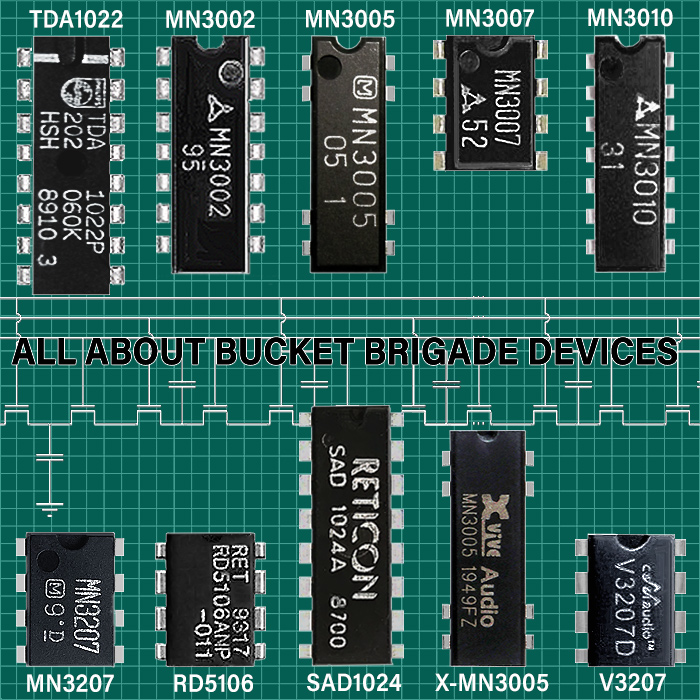

Note also that Capacitors form the basis of Bucket Brigade Devices - where several are combined in an Integrated Circuit / Chip.

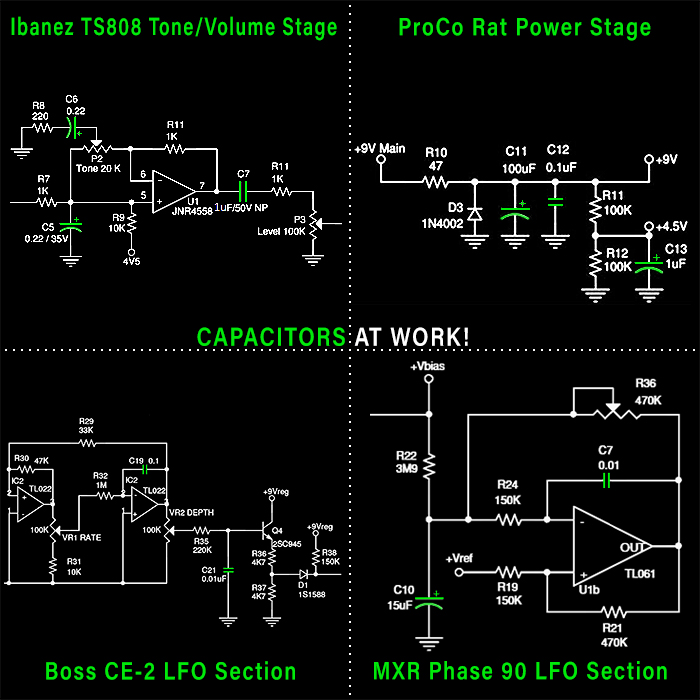

TONE SHAPING AND FILTERING - Ibanez TS808

The Ibanez Tube Screamer is a textbook example of tone shaping with capacitors. It uses a high pass filter at the input to roll off excess bass and a low pass filter in the tone control to shave off treble. Together, these filters create that signature mid boost that cuts through a mix without sounding harsh. This filtering happens after the gain stage, a bit like how a guitar’s tone control works, only more focused. You can hear the effect straight away when you roll the tone knob back — the top end smooths out without losing clarity.

COUPLING AND DECOUPLING - ProCo Rat

In the ProCo Rat, capacitors handle signal flow and power cleanliness. Coupling capacitors sit between each gain stage, blocking DC while letting the AC audio signal pass through. This stops unwanted offset voltages from stacking up across the OpAmp and prevents signal distortion where you do not want it. At the same time, a large electrolytic cap sits across the power rails to decouple high frequency noise and stabilise the power supply. Without it, the pedal would sound fizzy and pick up every hum in the room.

TIMING AND MODULATION - Boss CE-2

The Boss CE 2 chorus is a classic example of capacitors being used to set modulation speed and depth. In the low frequency oscillator circuit, capacitors charge and discharge to control how fast the waveform moves. These cycles are what make the chorus effect swoosh up and down. Swapping those timing caps is a common mod — it can make the sweep slower and more lush or faster and more warbly - depending on what you drop into the circuit. The same principle applies in tremolos and delays where the rate and repeat times are all shaped by capacitor values.

TIMING AND MODULATION - MXR Phase 90

The MXR Phase 90 is a cracking example of capacitors driving modulation. Inside, you’ve got a cap in the LFO that charges and discharges to set the sweep rate that’s what gives you that slow whoosh or fast warble depending on the value. It’s doing the same job as in a chorus or trem, just pushing phase shift stages instead. Swap out that timing cap and the whole feel of the pedal changes. Want it to swirl slowly like a vintage Uni-Vibe? Stick in a bigger value. Want it sharp and twitchy? Go smaller. It’s a dead simple change that completely shifts the character, all thanks to that one little capacitor doing its thing behind the scenes.

Insights into specific Capacitor Values

From Joe :

"The most common capacitor values I reach for in guitar pedals, especially for coupling caps, are 5nF, 10nF, 47nF, 100nF, and occasionally 220nF. These are usually film types, or sometimes paper in oil if I’m going vintage, rather than electrolytics. Electrolytic caps tend to show up more in power filtering or signal path sections where higher values are needed — things like 1µF, 10µF, 22µF, 47µF, and 100µF are all pretty standard in my builds.

That said, there are always outliers — take the classic Fuzz Face, for example, which famously uses a 2.2µF electrolytic as the input coupling cap. Once you’re up around 4.7µF or 10µF, the actual value doesn’t have a huge tonal impact in coupling positions — you’re pretty much passing the full EQ range either way."

A final note we've been asked to clarify is the ±10% etc. values - which are printed onto the side of most capacitors - these are essentially manufacturing tolerances - dependent on the precision and material nature of the capacitor makeup. For instance a typical ±10% tolerance on a capacitor means the actual capacitance value can vary by up to 10% above or below the marked value. For example, a 100µF capacitor with a ±10% tolerance could have an actual capacitance between 90µF and 110µF.

Class 1 ceramic capacitors, particularly those with an NP0 (C0G) dielectric, offer the highest tolerance and accuracy among commonly available capacitor types. They are known for their stability across voltage, temperature, and frequency variations, making them suitable for applications requiring precise capacitance values.

14 Key Iconic and Historic Audiophile Capacitors

Here Joe has done mini overviews for each of the 14 Capacitors featured in the main visual! :

SANGAMO GREEN CAPACITORS

These are straight from the tweed era. Sangamo greens have got that soft compression and harmonic bloom that vintage amp guys go mad for. In pedals, I love them in tone controls and fuzz voicings - especially the input cap. They round off the harshness and add a woody character. Rare now, but used to be common in American radio gear and early Danelectro/Sears amps. They can drift or leak, so always test — but when they’re good, they’re magic!

MULLARD MUSTARD CAPACITORS

These are straight up gold! Real Mustards from the 60s are what Marshall and Hiwatt were using. They’ve got this open, musical character that sings in tone stacks and drive circuits. They're not subtle either. Slightly rolled off highs, rich mids. Perfect in anything aiming for British amp style overdrive. Rare and getting rarer, but sometimes hiding in old British tape recorders or reel to reels. They usually test bang-on, unless they've been cooked. A bit of a status symbol in boutique builds, but for good reason.

PHILIPS BLUE SLEEVED CAPACITORS

These have a real following in hi fi, and for good reason. Philips blues are axial electros that sound full and detailed. I use them for audio path coupling when I want some vintage richness without going full paper in oil. Great in tone shaping stages or clipping sections, although with that said I much prefer Mullard mustard/tropical fish. You’ll find them in old tape decks, organ amps, and even some European studio gear. They’re surprisingly reliable, many still test bang on. Not boutique bling, but proper builder’s caps.

LEMCO MICA CAPACITORS

I’ll always grab these if I spot them. Lemco micas are tight tolerance silvered mica capacitors, often good up to radio frequencies, but I like them for tone circuits and octave fuzzes where clarity matters. They're stable, sound sharp and snappy, and don't drift over time like some old film types. Rare in the wild, but you sometimes get lucky in vintage military or test gear — think comms stuff, RF circuits. They test solid if not physically cracked. I like dropping them in early transistor fuzzes where I want precision but with a vintage feel.

AJAX BLUE MOLDED CAPACITORS

The kings of clean Fender tone. I was put onto these by the infamous amplifier tech Skip Simmons of The Truth About Vintage Amps Podcast (see episode 86 if you want to hear me absolutely star struck talking to him). The blue molded Ajax caps were all over blackface and brownface Fender amps. They are buttery smooth top end and lovely midrange detail. I like using them in bright voiced fuzzes or amp voiced preamp pedals. They also turn up in 60s Hewlett Packard test equipment labeled with their branding, proper treasure hunt stuff. Physically rugged and I have never found a bad one but test everything. When they’re good they bring that vintage American sparkle in spades. If i had to choose one type of cap to use it would be these.

SOVIET K40Y-9 CAPACITORS

Built like tanks. These Soviet PIO (Paper In Oil) caps are famous for their creamy mids and warm response. They’re perfect for tone shaping overdrives, treble boosters, fuzz or just about anything really. They take the edge off in a lovely way. Heavier and bigger than film caps, but worth the real estate if you want syrupy vintage tone. Still relatively easy to find from surplus sellers, though prices are creeping up. Most test well as they were made for military spec and it shows.

SPRAGUE BLACK BEAUTY CAPACITORS

These look the part but come with baggage. Sprague Black Beauties were all over vintage Gibson amps and guitars, big, bold, and instantly recognisable with that black body. They’re molded paper in plastic, not oil-filled, and while they’ve got a great vintage vibe for guitar circuits, they don’t hold up well for high voltage. I’ve seen them leak or drift way out of spec in old amps. Hi-fi guys absolutely slate them for that reason, but in a low voltage pedal circuit, I’ll use them if they test alright. They can sound warm and syrupy, especially in tone shaping stages or as coupling caps in fuzz or boost pedals. Rare, but they turn up in 50s and 60s American gear. This is one that you absolutely always have to test.

NICHICON GREEN MUSE CAPACITORS

These are workhorse electros with great tone. I like them in boost and drive pedals where I need stable low end filtering without the mush. The older green versions, you find them in stuff like the Keeley mod Boss pedals - have real charm and usually hold their values spec-wise. I’ll keep them if they test close. Not rare yet, but the vintage ones are drying up. I trust them more than most vintage electros. Great ESR (Equivalent Series Resistance), solid leakage figures if stored right.

MULLARD TROPICAL FISH CAPACITORS

If the Mustards are posh, the Tropical Fish are the funky cousins. Still PET film, but more common in late 60s and 70s gear. They’ve got this chewy, colourful voicing that suits phasers, choruses, and fuzz circuits down to the ground. I love them for shaping the character of mid forward overdrives. They add a high end sizzle that i rather like, they’ve got soul. Not super rare yet, but genuine ones are getting faked so watch out. Found loads in old radios and organ gear. Usually test alright unless they've been stored in damp sheds for 40 years!

WIMA RED BLOCK CAPACITORS

Reliable, consistent, and clean. WIMA red boxes are modern but they sound great. I use them when I want low ESR and tight tolerances without the vintage voodoo. Great in drive sections, tone controls, or anywhere you need predictable behaviour. Not rare, you can buy them new all day long but the older German ones from the 80s and 90s are particularly good. They test well, last forever, and look smart on a clean board. There’s a reason legends like Adrian Thorpe of ThorpyFx use them, of course I would put my hand in the fire to copy that man (for tonal reasons of course).

MURATA BLUE DISC CAPACITORS

These are the only ceramics I like seeing on a board. Murata blues are precise, reliable, and sound good, which can’t be said for a lot of ceramic caps. I like them in oscillators or for decoupling power rails, but they also work for fuzz tone shaping without the brittle harshness of cheaper ceramics although they are definitely not as sonically pleasing as other capacitors in this function. Still made today but the older Japan-made ones are best. They show up in Japanese gear from the 80s and 90s. Nearly always test good, Murata didn’t mess around!

DUBILIER GREENIE CAPACITORS

Dubilier electros are proper old school British caps, full of character when they’re still working. You’ll find them in valve radios, old military gear, and British-made amps and test equipment from the 50s through to the 70s. They’ve got that industrial feel, but truth be told, most of them don’t age gracefully. They were never designed to last 50 plus years. A lot of them now leak, drift, or go open circuit. That said, I’ll salvage them for nostalgia or for display in a vintage-correct build, but I test every single one before even thinking about using it. Sonically, when they’re good, they’ve got a bit of sag and warmth that suits older fuzzes and lo-fi preamps. But in anything critical or modern, I’ll swap them out for something reliable like a new Nichicon or Panasonic. Still, they’ve got that classic British valve tone vibe, and they look fantastic on an old turretboard.

GOLD WIMA COUPLING CAPACITORS (Paper or Film Dielectric)

These are absolute tone gold in more ways than one. The gold-bodied WIMA caps, often axial in orientation, showed up in some of the earliest British amps, like croc skin Selmers and JMI era Vox amps. They’ve got this rich, woolly response that adds instant vintage vibe to anything you drop them into. Perfect for coupling stages where you want warmth, bloom, and a bit of that old-school harmonic sag. They’re not the tightest or cleanest caps ever made, but that’s the point. Great in treble boosters, preamp voicing, and anything aiming for that early British jangle meets growl tone. Getting rare now though, you might spot them in old reel to reels if you’re lucky. I always test them first, as some can drift, but when they’re good, they’re dripping with mojo and bring a bit of Vox DNA into any build.

SPRAGUE WET TANTALUM CAPACITORS

Sprague wet tantalums are specialist caps, but I’ll use them when I want insane stability, especially in power sections or bias circuits. They’re overkill in most guitar pedals but brilliant in high voltage or filter heavy designs. Liquid electrolyte inside means they can fail catastrophically if abused - so always test. Extremely rare and pricey, but can show up in old aerospace equipment, high end lab gear or in my case, most military technology from the70’s and 80’s (Type 23 Frigates are a gold mine for these). Bit of a holy grail if you find working ones.

The myriad Capacitor Electrical Circuit Symbols and their meanings

Here we have all the Capacitor circuit symbols I could find - 28 in total. Some of these are now obsolete, and some as UK / US / EURO specific derivations - you will likely only see a handful of these on a circuit schematic - indeed as per the 4 examples above - where you can decipher those icons / symbols with the above chart.

The 28 types are split over 25 slots as follows :

- Non-Polar Fixed Capacitor

- Polar Electrolytic Fixed Capacitor

- Condenser with Power Connector

- Feed-Through-Capacitor

- Electrolytic Polarized Capacitor

- Capacitor with Outer Layer

- Armor Capacitor

- Polarized Fixed Capacitor

- Polarized Electrolytic Capacitor

- Variable Capacitor (2 x types)

- Polar Electrolytic Fixed Capacitor

- Bipolar Capacitor

- Differential Capacitor

- Supply Capacitor

- Electrolytic Cap Top Positive

- Older / Obsolete Capacitor Symbols (2 x types)

- Capacitor with Series Resistors

- Multiple Electrolytic Capacitors

- Voltage-Dependent Capacitor

- Temperature-Dependent Capacitor

- Trimmer Capacitor (2 x types)

- Preset Capacitor

- Split Stator Capacitor

- Dual-Ganged Variable Capacitor

- Variable Butterfly Capacitor

Hereby ends our presentation! We hope you enjoyed the journey!